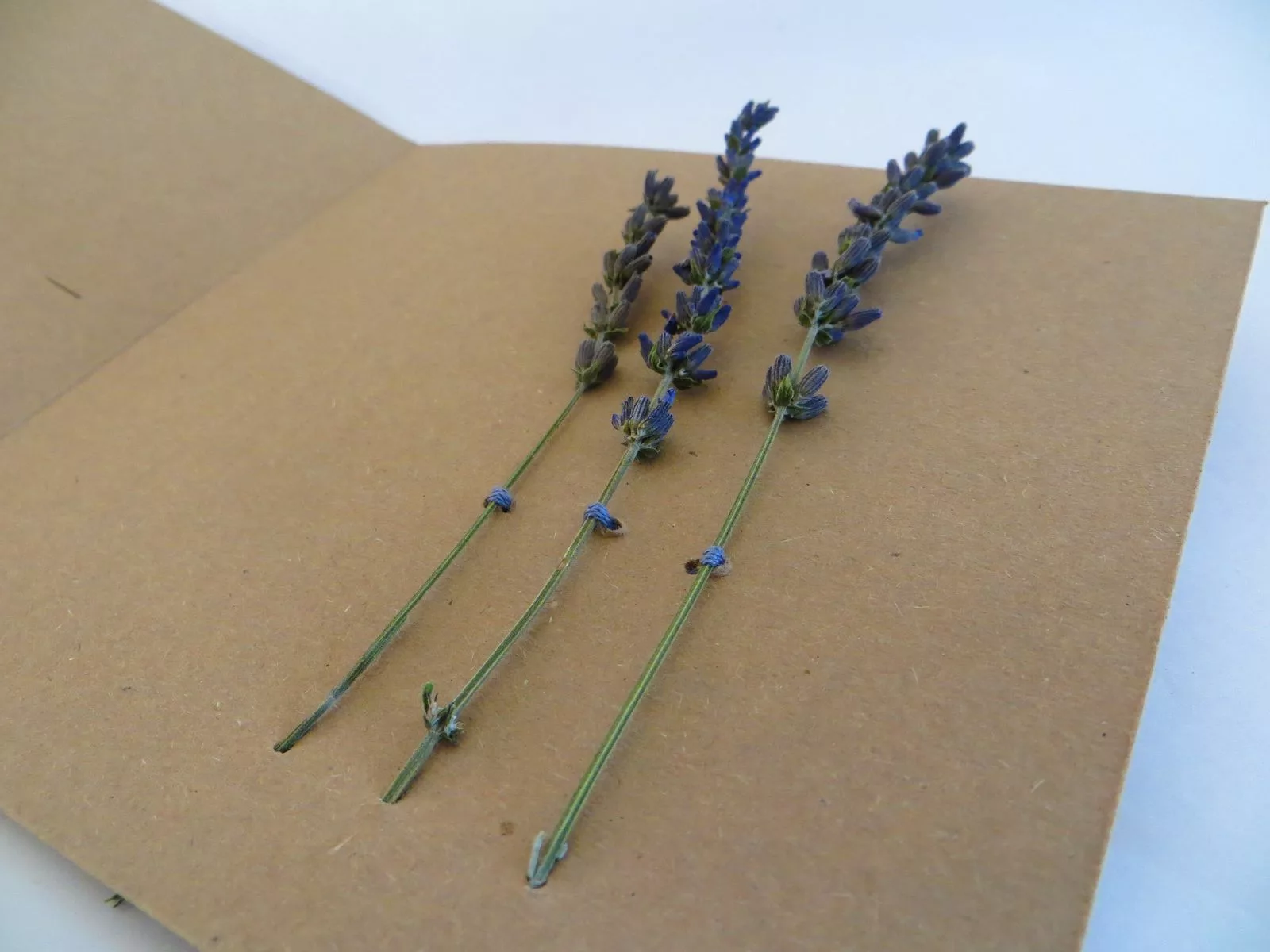

16 Sustainable gifts to buy or make

Sustainable gifts are not only more fun – especially when you make them yourself – but also good for the environment. Giving presents for the holidays, a birthday, a newborn or a wedding can be much more environmentally friendly. That is why I give you 16 Tips to make or buy sustainable gifts.